There is a big difference between chrome versus stainless steel, especially in medical equipment manufacturing. Stainless steel shows it’s longevity by it being chosen as a building material in some of the longest lasting architecture features in the world. Chrome is used in automobile manufacturing and looks great when new but ages and corrodes rather quickly. In the healthcare setting, usage varies by department. When purchasing new equipment, please be sure you know the difference.

Perhaps one of the most iconic buildings erected from stainless steel is famous Chrysler Building in New York City. Construction finished in 1930 and the stainless steel on the exterior of the building has been cleaned only twice. If you have ever been in Manhattan on a beautiful sunny day, you can’t help but notice the distinctive top of the Chrysler Building. The last time it was cleaned was over 20 years ago. This shows how durable and long lasting stainless steel is. Over 86 years old and still the original material and it still looks great. We don’t expect the stainless steel to last that long in your OR, but it is a durable material when compared to chrome.

The automobile industry has used chrome extensively in past years. However, because of the properties of chrome deteriorating, the usage has been reduced in recent years. It has been replaced with plastic and aluminum which do not deteriorate so quickly. To see how long chrome can last, just look around in the parking lot. Many vehicles that are 2-3 years old have chrome pieces on them that are deteriorating and rust. The extent of this depends directly on the environment and how the vehicle is cared for. Because of the demanding healthcare environment, this becomes a great concern. Harsh cleaners and disinfectants are use to keep the equipment clean and safe which causes deterioration to start. This causes chrome equipment to have a rather short life cycle. Make sure you know what you are purchasing and how it will last before you cut the purchase order.

Stainless Steel

What is Stainless Steel?

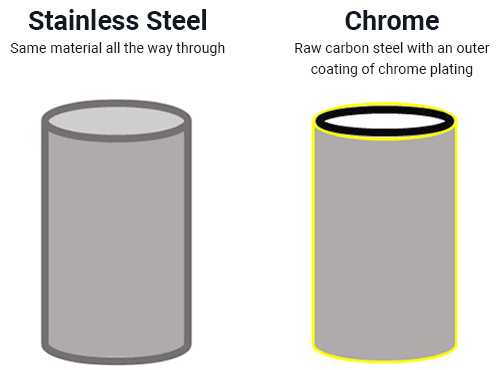

Stainless steel is a metal alloy, made up of steel mixed with elements such as chromium, nickel, molybdenum, silicon, aluminum, and carbon. Different formulas of these materials create different grades of stainless steel. 304 stainless steel is used in most medical equipment. It has between 8 and 10 % nickel content. It is the same material through out so if it gets scratched or cut, no problem, the material below is the same as what is on the surface. Stainless steel will not rust and has no magnetic properties.

How long does it last?

Stainless steel can last for many years as shown in the example of the Chrysler building above. What takes it out of service in a medical facility is that it is bent or is no longer operational, not because it has rusted or corroded. Stainless steel is 100% recyclable.

Where can stainless steel be used in healthcare facilities?

Stainless steel can be used in any healthcare environment. With it’s easy to clean surface and longevity, cleaning and infection control is easy. Many facilities are using stainless steel in IV Poles and other high use equipment, hospital wide. It makes their jobs so much easier that it is worth the small amount they pay more for a superior product.

How can I tell the difference?

- This is your no fail go to test. If a magnet will stick to it, it is not stainless steel. Stainless steel is not magnetic.

- Chrome has a bright shine to it, stainless steel is often a satin finish, However you can not always go by appearance, some types and finishes of stainless steel are very shiny.

Are there different types or grades of stainless steel?

Yes. There are many different alloys of stainless steel. Here are the two main alloys.

- #304– This grade is used in the medical industry. It has a 18% chromium and 8% nickel composition. It is specified for operating rooms and many food service applications.

- #316– This grade is used in corrosive environments like in products that come in contact with sea salt and acids. It has a 16% chromium and 10% nickel and 2% molybdenum. The molybdenum is added to help resist corrosion to chlorides (like sea water and de-icing salts). Normally this grade of stainless steel is not required in a medical setting.

For more information on stainless steel click here.

Chrome

What is Chrome?

Chrome is a coating applied to steel for protecting the steel. There are different grades of chrome made up of different metals. As long as the surface remains intact, chrome is a good product. It looks great with a high luster finish and helps protect the material under it from rust and corrosion.

How long does it last?

Cared for correctly, Chrome can last for several years. In low usage areas and dry environments it is durable. As soon as the Chrome coating is penetrated you have exposed raw steel and that rusts and corrodes. That coating can be penetrated by bumping the wall or doorway, clamping attachments on to a chrome tube, by a metal tool or instrument sliding across the surface, or even the sharp edge of a table or other piece of equipment. Once the protective surface of the chrome is penetrated, the rust and corrosion spreads under the chrome layer and it loosens and fall off, exposing more raw steel. This makes it an infection control issue in healthcare facilities.

Where can chrome be used in healthcare facilities?

Chrome can be used in clinics, patient rooms, and some long term care areas. Due to the environment it’s use is discouraged in Operating rooms. It does not stand up well to the cleaners and high use of the operating room.

Recent Comments